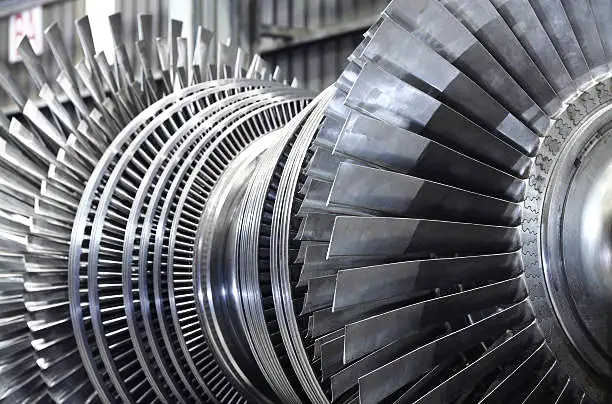

Steels for steam turbine blades we produce:

Steel used for steam turbine blades is typically a high-performance alloy that is designed to withstand the high temperatures and stresses of the turbine environment. These alloys are usually based on nickel, cobalt, or iron, and may contain a variety of other elements, such as chromium, molybdenum, and tungsten.

One commonly used alloy for steam turbine blades is Inconel, which is a nickel-chromium alloy that exhibits excellent high-temperature strength and resistance to oxidation and corrosion. Another popular alloy is Hastelloy, which is a nickel-molybdenum-chromium alloy that is known for its exceptional resistance to a wide range of corrosive chemicals and environments.

The specific properties of the steel used for steam turbine blades will depend on the requirements of the turbine design and the operating conditions of the turbine. Some key properties that are typically desired include high strength, high resistance to corrosion and oxidation, good fatigue resistance, and excellent dimensional stability.

The manufacturing process for turbine blades involves a combination of casting, forging, and machining operations to produce a finished product with the required shape and properties. Quality control is critical throughout the manufacturing process to ensure that the finished blades meet the necessary specifications and can perform reliably in the demanding turbine environment.

UNS S4500, XM-25, GTD 450, Alloy C450, GE B50A789; UNS S4200, AISI 422, AISI 616, B4B, SUH616, 10705BP, 10705BAA/10705AG, 10705BU, 10705MBU, GE B50A951, B50A365 B, B50A790(403Cb), B50A947A4, B50A947B2, B50A948, B50A789G

Aerospace »

1.4418, X4CrNiMo16-5-1, Z8CND17-04 Martensitic stainless steel have high tensile properties combined with excellent ductility and better corrosion resistance than the common type 400 series martensitics. acc. to EN 4628-2013, AIR 9160/C

Non-Magnetic Steel »

Power,Energy, Drill Collars, Nonmagnetic Stainless Steels, magnetic permeability of μr max 1.01. 1.3813, X40MnCrN19 non-magnetic steels, rust and acid resistant. 1.3813 is often supplied in a hot-cold-formed form.

Special steel & Stainless steel »

1.4037, X65Cr13, 65Ch13 ,420D stainless steel is characterised by its high hardenability in conjunction with good corrosion resistance in moderately corrosive environments.

Fasteners, Spare Parts, Maintenance Materials »

Supplying materials worldwide for the production and maintenance of Steam and Gas Turbines. Materials spec. acc. to GE, Siemens, Alstom, Skoda, Harbin Turbine, Shanghai Turbine, Dongfang Turbine. Nimonic 80A, 1.7362, A194 Grade 3, Type 501, UNS S50100

Materials we constant supply:

- XM-25, UNS S45000, 1.4594, X5CrNiMoCuNb14-5, Custom 450, B50A789

- 403Cb, 410Cb, B50A790, XM-30, UNS S41040

- 1.4923, X22CrMoV12-1

- AISI 403, AISI 410, UNS S40300, UNS S41000

- Nimonic 80A, Alloy 80A, UNS N07080, 2.4952

- 1.4913, X19CrMoNbVN11-1

- 1.4938, X12CrNiMoV12-3, UNS S64152, M152

- 1Cr11Ni2W2MoV, 13Cr11Ni2W2MoV, 13Х11Н2В2МФ, 1Х12Н2ВМФ

Our stock in stock, various dimensions and materials in stock

| Grade | Shape | Dimension(mm) | Quantity(Kg) |

|---|---|---|---|

| XM-25 Solution Annealed Bright Bar | Round | Φ30 | |

| Alloy C450, GTD 450, XM-25, UNS S45000, B50A789 Round Bar | Round | Φ150 | 3626 |

| 1.4037, X65Cr13 round bar flat bar | Round | Φ60 | 25000 |

| 15-5PH, 1.4545, UNS S15500, X5CrNiCuNb15-5 | Round | Φ40-Φ190 | |

| 1.3813 X40MnCrN19 cold drawn bar | Round | Φ48 | 895 |

| 1.7711, 40CrMoV4-7, 40CrMoV4-6, UNS K14072 | Round | Φ55 | 1986 |

| 1Cr11Ni2W2MoV, 13Cr11Ni2W2MoV, 961 Round bar, Forgings, ESR Ingot | Round | φ16 | 334 |

| 17-4ph, X5CrNiCuNb16-4, AISI 630, S17400, 1.4542 | Ingot | Φ410/Φ380 x 1210 | |

| 1.6932, 28NiCrMoV8-5 | Round | Φ70 | 3912 |

| A194 Grade 3, Type 501, 1.7362, 12CrMo19-5 | Round | Φ45 | 2855 |