GTD 450 Blades of Gas Turbine Material

Custom 450® stainless is a martensitic age-hardenable stainless steel(Precipitation hardening stainless steel) which exhibits very good corrosionresistance (similar to that of Stainless Type 304) with moderate strength (similar to that of Stainless Type 410).The alloy has a yield strength somewhat greater than 100 ksi (689 MPa) in the annealed condition, but is easilyfabricated. A single-step aging treatment develops higher strength with good ductility and toughness.This stainless can be machined, hot-worked, and cold-formed in the same manner as other martensitic age-hardenable stainless steels. A particular advantage is ease of welding and brazing. GTD 450 stainless is generally supplied in the annealed condition, requiring no heat treatment by the user formany applications. Because it has corrosion resistance like Type 304 stainless but three times the yield strength, ithas been used in applications where Type 304 was not strong enough. On the other hand, it has also replacedType 410 stainless directly on a strength basis where Type 410 had insufficient corrosion resistance. Mechanicalproperties will depend on the aging temperature selected.

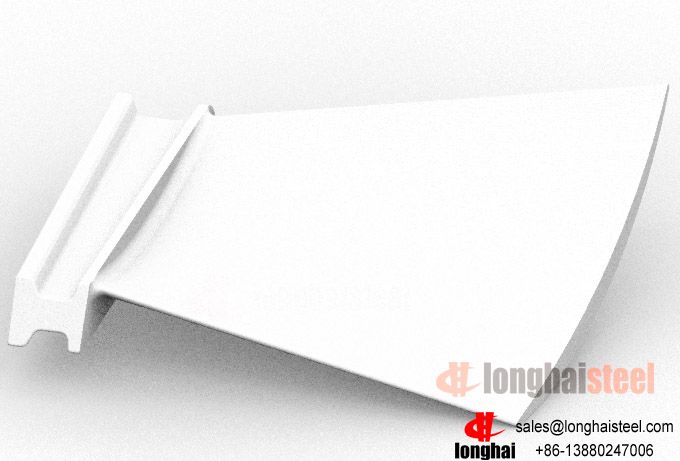

Compressor blading materials for land based gas turbines – Special steels Until recently, all production blades for compressors are made from 12% chromium containing martensitic stainless steel grades 403 or 403 Cb (Schilke, 2004). Corrosion of compressor blades can occur due to moisture containing salts and acids collecting on the blading. To prevent the corrosion, GE has developed patented aluminum slurry coatings for the compressor blades. The coatings are also meant to impart improved erosion resistance to the blades. During the 1980’s, GE introduced a new compressor blade material, GTD-450, a precipitation hardened martensitic stainless steel for its advanced and uprated machines Without sacrificing stress corrosion resistance, GTD-450 offers increased tensile strength, high cycle fatigue strength and corrosion fatigue strength, compared to type 403. GTD-450 also possesses superior resistance to acidic salt environments to type 403, due to higher concentration of chromium and presence of molybdenum

Custom 450 stainless shows excellent resistance to oxidation up to approximately 1200ºF (649ºC). Significantaging occurs when annealed material is heated to 700ºF (371ºC) and higher.Long-term exposure to elevated temperatures can result in reduced toughness in precipitation hardenablestainless steels. The reduction in toughness can be minimized in some cases by using higher aging temperatures.Short exposures to elevated temperatures can be considered, provided the maximum temperature is at least 50ºF(28ºC) less than the aging temperature.

Corrosion Resistance

Custom 450 stainless has resisted atmospheric corrosion including salt water atmospheres. It shows excellentresistance to rusting and pitting in 5% and 20% salt spray at 95ºF (35ºC). Tests in hot concentrated nitric acidshow corrosion resistance approaching that of Type 304.Optimum corrosion resistance for this alloy is obtained in the annealed condition. However, age hardening results inonly a slight change.For optimum corrosion resistance, surfaces must be free of scale, lubricants, foreign particles, and coatings applied