About 422 5 results

Dynamic Recrystallization of AISI 422 Stainless Steel During Hot Deformation Processes

Dynamic recrystallization (DRX) process ofa martensitic stainless steel (AISI 422) at temperatures of950, 1000, 1050, 1100 and 1150oC and strain rates of 0.01, 0.1 and 1 s21.

AISI 422 Stainless Steel experiment and method

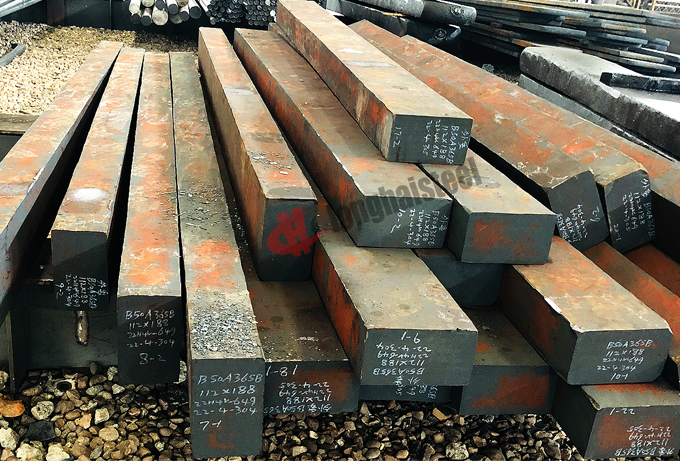

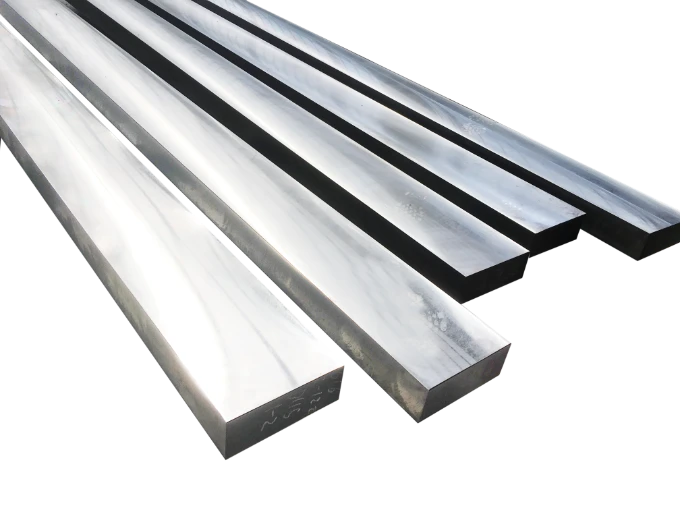

The steel used in the experiment is 422 martensitic stainless steel, its chemical composition is shown in Table 2.1, and the original heat treatment state is hot-rolled and annealed

Application and Development of 422 Stainless Steel

Due to supercritical (initial steam pressure of 24MPa, initial steam temperature and reheating temperature of 566°C/566°C) and ultra-supercritical (initial steam pressure of 25MPa, initial steam tempe

Thermoplastic Forming Behavior and Microstructure Evolution of 422 Super-critical Blade Steel

Thermoplastic Forming Behavior and Microstructure Evolution of 422 Super-critical Blade Steel

AISI 422, SUH 616, B50A951, 1.4935, X20CrMoWV12-1

AISI 422, 1.4935, X20CrMoWV12-1, B50A249 S12, B50A951, martensitic stainless steels are high-alloy steels mainly used turbine blades, power plants