Thermodynamic calculation of equilibrium phases in Custom 450 stainless steel

Custom 450 is awidelyused maragingstainlesssteel, and the melting method and chemical composition vari ations in different batches have a significant effect on its properties. The composition and content of equilibrium phases at various aging temperatures were investigated bythermodynamic software Thermo-Calc, and the effects ofC, N and Nb contentwerealsodiscussedbyanalyzingroomtemperaturemechanical properties together with thermodynamics. The results indicate that the equilibrium phases between 760~640℃ comprise a, y,o,NbNi,, FCC-Cu, MzC6, Nb(CN)andasmallamountofZCrNbNLavesandxwith the increasing of aging temperature, the UTS and YS de-crease with thetransitionofequilibriumphasesandthereduction oftotal mass fraction of precipitations; in addition,the fraction of carbides and carbonitrides increase and the fraction of intermetallic decrease with the increasing of C and N content:the increasement ofNb content shows little effect on the fraction of carbides and carbonitrides, but improves the fraction ofintermetallics.

Custom 450 is a martensitic aging-strengthened stainless steel. Because the alloy has similar corrosion resistance to 304 austenitic stainless steel, it can reach the strength level of 410 series martensitic stainless steel. In addition, because it does not contain more expensive Co Elements, low cost, so widely used in aerospace, marine ships and other fields. The steel has a yield strength of about 690MPa in the solid solution state, and has good processing performance: after a simple one-step aging treatment, it can obtain higher strength, and the transverse direction of large cross-sectional parts still has good plasticity and toughness[1 -4. In the actual production process, due to the different smelting methods adopted and the resulting batch differences in the content of alloying elements, especially the content of C and N [13], the precipitation amount and precipitation temperature of the precipitation strengthening phase during the aging process will be significantly affected. affect the final mechanical properties. In this paper, a certain heat of Custom 450 steel was taken as the research object, and the tensile and impact properties at room temperature were tested at different aging temperatures. , Nb content on the influence of equilibrium precipitation law, the analysis results can provide some theoretical guidance for the composition design and heat treatment process of the alloy.

Test materials and methods

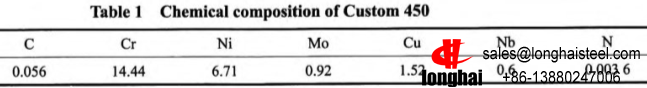

The test alloy was smelted in a 25kg vacuum induction furnace + vacuum self-consumption remelting, and then forged into a φ18mm round bar. The main chemical composition:

The measured results are shown in Table 1. The solid solution temperature is 1040℃, the holding time is 1h, and then oil-quenched to room temperature; the aging temperatures are 482, 510, 538, 566, 593, 621°C, the holding time is 4h, and then air-cooled to room temperature.

The calculation of thermodynamic equilibrium phase adopts Thermo-Calc software and TCFE-7 database, taking the measured chemical composition in Table 1 as the input condition, calculates the phase mass fraction-temperature diagram within the aging temperature range, and adjusts the C, N, Nb content respectively, The influence of element mass fraction on equilibrium precipitate type and equilibrium precipitate mass fraction was comparatively analyzed.

Test Results and Discussion

Tensile mechanical properties at room temperature

The room temperature tensile and impact mechanical properties of the test steel after solution quenching and aging at different temperatures are shown in Figure 1, where the first point is the state of quenching to room temperature. It can be seen that after aging for 4 hours in the temperature range of 480-620 °C, the yield strength and tensile strength of the test steel decrease continuously with the increase of temperature, and the peak strength is reached after aging at a lower temperature of 480 °C, and the impact absorption energy of the material is the lowest at this time. Precipitated phases aged at low temperature have smaller average diameter and higher number density, and the strengthening effect of the second phase is greater. As the aging temperature rises, on the one hand, a certain volume fraction of reverse-transformed austenite may appear, which reduces the strength and improves toughness; Second phase reinforcement. Therefore, the following thermodynamic calculation of the phase composition type and quantity within the aging temperature range can provide a certain theoretical basis for the composition design of steel and the optimization of heat treatment process.

Equilibrium Phase Composition of Custom 450

The mass fraction of the equilibrium phase in the range of 400-640 °C obtained by the Thermo-Calc thermodynamic calculation software is shown in Figure 2. It can be seen that within this temperature range, as the temperature rises, accompanied by the transformation of the matrix a to the γ phase, the possible precipitated phases include σ, NbNi, FCC-Cu, Mz3C6 Nb(C,N), and a very small amount appears below 540 °C In Z-CrNbN, a very small amount of Laves phase and x phase appear in the temperature range of 590~640 ℃.

The red dotted line in Figure 2 shows the sum of the equilibrium mass fractions of all second phases except the matrix phase a and γ. It can be seen that as the temperature increases, the total equilibrium mass fraction of the second phase decreases continuously, which is mainly related to the precipitation of the σ phase. associated with a reduction in driving force. The σ phase with a higher mass fraction belongs to the topological close-packed phase (TCP phase), and its main alloying elements are Fe, Cr, and Mo. Since this phase is hard and brittle, its influence on the properties of the alloy depends on its precipitation form, location and quantity. 7; In addition, due to the σ phase and MzC, there is a coherent relationship between the phases, Mz;C. When the phase precipitates on the grain boundary, the 0 phase usually nucleates on the Mz3C phase on the grain boundary8, and the precipitation at the grain boundary leads to a significant decrease in the corrosion performance of the alloy.

Therefore, the formation of a large number of fine and dispersed Cu-rich phases during the aging process is one of the main strengthening methods of the steel, which is similar to 17-4PH and 15-5PH. When the Cu particle size of the spherical BCC structure reaches 2.3~3nm, the material reaches the peak strength, and as the aging time prolongs, the Cu particle loses the coherent relationship with the matrix and transforms into 9R and 3R structures in turn, and the final equilibrium state is FCC with disc shape. Structure e-Cu9-10]. The steel contains 0.6% Nb element by mass fraction. According to the thermodynamic calculation results, NbNi and Nb(C,N) precipitates are formed in different temperature ranges, among which Z-CrNbN has a tetragonal structure. The precipitation of Z phase can be observed in martensitic heat-resistant steel after long-term service at 600-660 °C. High Cr content accelerates the precipitation of Z phase and thus accelerates creep instability, and its precipitation is related to MX-type carbonitrides [11]. Due to the high thermal stability of Nb(C,N) with face-centered cubic structure, it can only be partially dissolved after a relatively high solid solution temperature, and its content is generally not affected by the heat treatment system. Therefore, the primary Nb(C,N) precipitated during solidification N) has a significant effect of inhibiting grain growth.

Table 2 lists the chemical composition and phase content of the equilibrium second phase in steel at 510, 565 and 621 °C. It can be seen that interstitial elements C and N are important strengthening phase-forming elements in Custom450 steel, and their content has a significant effect on the second phase Quantity has a great influence. In addition, the relevant standards only stipulate C content but not N content, and the range of Nb content is also wide. There may be large batch differences in the actual production process. Therefore, it is necessary to discuss the C, N, and Nb elements. The effect on the type and quantity of equilibrium precipitation can provide a certain theoretical basis for the study of the strengthening and toughening mechanism of the steel and industrial production.